- RPE, The Last Level of Protection

- Preferred Measures for Controlling Exposure

- Scenarios Where RPE may be Required

- An Effective RPE Programme

- Nuisance Dust Masks Not Permitted

RPE, The Last Level of Protection

Before considering the use of Respiratory Protective Equipment (RPE), a risk assessment must be undertaken and measures that reduce exposure by other means, such as local exhaust ventilation, must be implemented first. In other words, RPE should only be used as a last level of protection when working with substances that are known to be, or may reasonably be expected to be, hazardous via inhalation and where control of exposure cannot be achieved via other means.

- RPE is an intrusive equipment.

- Not many people would willingly want to wear RPE for any length of time, it can be uncomfortable to wear.

- RPE can cause disturbance to make-up, jewellery and hair style.

- RPE may interfere with communication and vision.

- RPE can interfere with the wearer’s personal freedom such as wanting to have a goatee, beard or to come to work with stubble.

- RPE can give a sense of false protection, especially when not worn in accordance with the manufacturer’s instruction.

- RPE can be expensive in the long run when compared to simple, common sense control measures.

- RPE can only protect the wearer. Control measures at source (at the point where hazardous substances are released into workplace air), such as local exhaust ventilation or enclosures, protect all those working in the area when used properly.

Preferred measures for controlling exposure

In order of priority, the preferred measures for controlling exposure are:

- Eliminate the hazardous substance.

- Substitute for a safer alternative substance.

- Use a safer form of the substance.

- Enclose the task to prevent the substance escaping into the workplace air.

- Modify the process so less substance is given off.

- Extract emission (E.g. vapour, gases, dust) from substances.

- Minimise the number of workers exposed.

- Minimise the length of time each worker is exposed.

Note: as many of the above as necessary can be applied in combination.

Scenarios Where RPE may be Required

ONLY if none of the other control measures adequately reduces the level of exposure, may it be necessary to resort to using RPE. Examples of scenarios where RPE may be required:

- When you might still breathe in contaminated air, despite other controls you have in place.

- When there is short-term or infrequent exposure and using other controls is impractical.

- Whilst you are putting other controls in place.

- When you need to provide RPE for safe exit in an emergency.

- When you need to provide RPE for emergency work or when there is a temporary failure of controls.

- When emergency rescue by trained personnel is necessary.

Note: as part of your risk assessment, you must justify the reasons behind your decision to use RPE.

An Effective RPE Programme

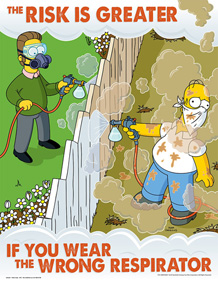

To ensure RPE works effectively, a strict RPE programme must be followed. Any shortcomings in one of the steps in the programme could result in wearers not receiving adequate protection. The programme should ensure that:

The correct type of RPE is selected, i.e. it gives adequate protection against the inhalation hazard and is suitable for the task, the operating environment and the wearer. Contact SLS Safety for advice.

The correct type of RPE is selected, i.e. it gives adequate protection against the inhalation hazard and is suitable for the task, the operating environment and the wearer. Contact SLS Safety for advice.- Face fit testing is carried out for each wearer, for each piece of tight-fitting RPE they use. This is a statutory requirement. Contact SLS Safety to arrange a face fit test.

- The RPE works with other protective equipment the user wears.

- The wearers are trained to use it and are supervised to ensure correct use as per their training.

- Wearers check to ensure RPE is working correctly before each use.

- Wearers maintain each device as per the manufacturers’ instructions.

- Wearers store their RPE properly.

- Training, fit testing and maintenance checks are recorded.

Nuisance Dust Masks Not Permitted!

Use of nuisance dust masks is not permitted under any circumstances! Some suppliers sell products known as nuisance dust masks or comfort masks that look like dust respirators but are not marked with CE or with any standard. They often have only one head strap. These are not intended for use when a respirator should be worn. You should never use a nuisance dust mask instead of an approved respirator. Packaging for these masks might be labelled, ‘This product does not provide respiratory protection’, or something similar.